Excellent surface treatment expert, customized vibration finishing solutions for multiple industries

- An assortment of Mass Finishing Equipment

- High Power Motor supported by NSK bearing

- High-Quality HD90 PU Lining from Dow Chemicals

- Descaling, Deburring, Degreasing, Pre-anodize Finish, Polishing

* A professional surface treatment expert will contact you within 24 hours.

Car

Car

Car

Car

Car

Car

Car

Car

Car

Car

Car

Car

Car

Inovatec Machinery

Inovatec Machinery has all solutions for your mass finishing applications.

Besides our standard design, there is a wide selection of smaller batch sizes and massive tub styles for big parts. In addition, OEM design is also available with your own color and logo.

Inovatec machinery manufactures go-to finishing systems for batch and continuous parts finishing. These machines can finish small, medium, and large parts. It can do all the finishing processes like deburring, degreasing, descaling, edge breaking, radiusing, cleaning, surface smoothening, preparation, and polishing. We carry a wide selection of feature-laden vibratory finishing systems for just about any purpose.

Vibratory Deburring Machine: Model VBS(B)

The VBS(B) series vibratory deburring machine is useful for materialremoving, cleaning

- Capacity 400 liter

- PU thickness 25mm

- Motor Power: 5 KW

- Machine Weight: 780kg

- Easy separation for parts and meda

Vibratory Deburring Machine: Model VBS(B)

The VBS(B) series vibratory deburring machine is useful for materialremoving, cleaning

- Capacity 400 liter

- PU thickness 25mm

- Motor Power: 5 KW

- Machine Weight: 780kg

- Easy separation for parts and meda

Vibratory Deburring Machine: Model VBS(B)

The VBS(B) series vibratory deburring machine is useful for materialremoving, cleaning

- Capacity 400 liter

- PU thickness 25mm

- Motor Power: 5 KW

- Machine Weight: 780kg

- Easy separation for parts and meda

Vibratory Deburring Machine: Model VBS(B)

The VBS(B) series vibratory deburring machine is useful for materialremoving, cleaning

- Capacity 400 liter

- PU thickness 25mm

- Motor Power: 5 KW

- Machine Weight: 780kg

- Easy separation for parts and meda

Vibratory Deburring Machine: Model VBS(B)

The VBS(B) series vibratory deburring machine is useful for materialremoving, cleaning

- Capacity 400 liter

- PU thickness 25mm

- Motor Power: 5 KW

- Machine Weight: 780kg

- Easy separation for parts and meda

Vibratory Deburring Machine: Model VBS(B)

The VBS(B) series vibratory deburring machine is useful for materialremoving, cleaning

- Capacity 400 liter

- PU thickness 25mm

- Motor Power: 5 KW

- Machine Weight: 780kg

- Easy separation for parts and meda

Vibratory Deburring Machine: Model VBS(B)

The VBS(B) series vibratory deburring machine is useful for materialremoving, cleaning

- Capacity 400 liter

- PU thickness 25mm

- Motor Power: 5 KW

- Machine Weight: 780kg

- Easy separation for parts and meda

Vibratory Deburring Machine: Model VBS(B)

The VBS(B) series vibratory deburring machine is useful for materialremoving, cleaning

- Capacity 400 liter

- PU thickness 25mm

- Motor Power: 5 KW

- Machine Weight: 780kg

- Easy separation for parts and meda

Vibratory Deburring Machine: Model VBS(B)

The VBS(B) series vibratory deburring machine is useful for materialremoving, cleaning

- Capacity 400 liter

- PU thickness 25mm

- Motor Power: 5 KW

- Machine Weight: 780kg

- Easy separation for parts and meda

Before and After

Inovatec machinery manufactures various types of tumbling media. It includes plastic media, ceramic media, stainless steel media, high density media, and organic media. High quality media is guaranteed with the help of strict manufacturing guidelines. So, a high quality finish can be achieved in a short processing time.

Surface polishing steps

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

• First, determine the type of surface treatment your workpiece needs: deburring or polishing.

• Choose the appropriate abrasive type based on the purpose of the treatment:

• Polishing: Use steel balls or polishing balls

• Deburring: Use ceramic deburring abrasives

• Generally speaking, the abrasive should be slightly smaller than the workpiece to facilitate sorting and ensure full contact with the workpiece surface.

• Also ensure that the abrasive does not get stuck in holes or gaps in the workpiece, which can affect the treatment and subsequent cleaning.

• Add the appropriate amount of abrasive and workpiece to the machine:

• Typically, vibratory grinders should be filled with about 70–80% abrasive by volume

• For deburring, the abrasive to workpiece volume ratio is about 3:1

• For polishing, the abrasive to workpiece volume ratio is about 6:1

• Add appropriate amount of water and grinding fluid:

• Tap water can be used

• For a 100L vibrating machine, it is recommended to add 100-200g of grinding fluid

• The amount of water is only enough to wet the abrasive and workpiece

• You can also pre-mix the grinding fluid and water at a concentration of 3% and pour it into the equipment

• Start the machine and set the grinding time (e.g. 1 hour):

• Polishing time is generally 30–60 minutes

• Deburring time is generally 1–2 hours

• It is recommended to check the workpiece status every 30 minutes and take out 1–2 pieces for comparison and observation

• After grinding, the workpiece needs to be cleaned and dried thoroughly

• For metal workpieces that are prone to rust, it is recommended to soak them in anti-rust liquid first and then dry them

• After each use, the abrasive must be cleaned thoroughly to remove the remaining grinding fluid and impurities for the next use.

Customized polishing solutions

Optional Design & Setting

Inovatec machinery manufactures various types of tumbling media. It includes plastic media, ceramic media, stainless steel media, high density media, and organic media. High quality media is guaranteed with the help of strict manufacturing guidelines. So, a high quality finish can be achieved in a short processing time.

The proper ratio of water and the appropriate compound can be ensured with the help of the Prominent dosing pump.

The proper ratio of water and the appropriate compound can be ensured with the help of the Prominent dosing pump.

The proper ratio of water and the appropriate compound can be ensured with the help of the Prominent dosing pump.

The proper ratio of water and the appropriate compound can be ensured with the help of the Prominent dosing pump.

The proper ratio of water and the appropriate compound can be ensured with the help of the Prominent dosing pump.

The proper ratio of water and the appropriate compound can be ensured with the help of the Prominent dosing pump.

Mass Finishing Media

Inovatec machinery manufactures various types of tumbling media. It includes plastic media, ceramic media, stainless steel media, high density media, and organic media. High quality media is guaranteed with the help of strict manufacturing guidelines. So, a high quality finish can be achieved in a short processing time.

- Low wearing long life tumbling media made for your parts

- 1mm to 100mm size available for big and small parts

- Ceramic media, plastic media, steel media full range media for selection

- China Factory direct wholesales price with low MOQ

Largest manufacturer of high quality plastic & ceramic tumbling media

Annual export of 3000 plus machines

Ability to customize machine according to customer requirements

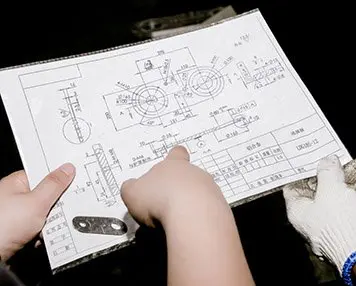

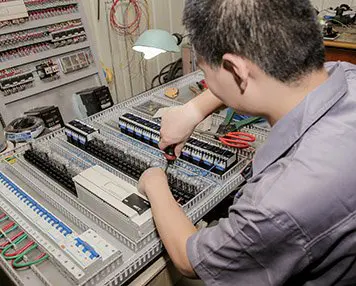

Our Factory

Inovatec machinery manufactures various types of tumbling media. It includes plastic media, ceramic media, stainless steel media, high density media, and organic media. High quality media is guaranteed with the help of strict manufacturing guidelines. So, a high quality finish can be achieved in a short processing time.

Frequently Asked Question

Inovatec machinery manufactures various types of tumbling media. It includes plastic media, ceramic media, stainless steel media, high density media, and organic media. High quality media is guaranteed with the help of strict manufacturing guidelines. So, a high quality finish can be achieved in a short processing time.

MOQ for vibratory finishing machine is one pcs.

We use a wooden box to protect the vibratory finishing machine during the shipment. The forklift can lift the machine and easy to remove in the workshop.

Our nearest port is Shanghai Ningbo and Yiwu. We can ship to other locations that you prefer.

Yes, we offer free sample processing. You can send us enough amount of your parts and we will test in our lab. We also need your surface requirement, for example, a reference part with desirable surface finishing. We will send the parts back to you for evaluation after finishing.

You can either come personally or you can book an independent inspector to check machine quality in our workshop. If you need any photo or video we are happy to provide you.

Guidelines for Surface Polishing of Industrial Products

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Inovatec Machinery Customer Reception Process

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Choosing the Right Mass Finishing System: A Comprehensive Guide

Mass finishing is an automated mechanical and chemical process that refines both simple and complex workpieces. It uses equipment, media, and compounds to transfer energy to the parts being processed. This allows the media to flow around the workpieces, either wet or dry, handling many parts simultaneously. Essentially, mass finishing involves the continuous flow and vibration of abrasive media around non-fixed parts, causing them to move randomly within the media mass.

Step-by-Step Guide to Selecting the Right Mass Finishing System

Choosing the right mass finishing system requires considering several factors, including labor, production time, budget, and part characteristics. Here’s a step-by-step guide to help you choose:

Step 1: Understand Mass Finishing Techniques

While many machines exist, the most common are barrel tumblers and vibratory tumblers. Other options include centrifugal disc finishing machines and centrifugal barrel finishing machines.

- Barrel Tumbler: This system works by lifting and dropping parts as the barrel rotates, creating abrasion as parts rub against media and other system components. Barrel tumblers apply greater force, resulting in a more uneven surface with rounded corners and more material removal. They’re good for “brute force” finishing and can achieve a quick luster through peening with steel shots.

- Vibratory Tumbler: Here, the cutting material surrounds the parts, and a rotating weight shakes the tub in a circular path. This lifts and drops the load, creating a shearing action between parts and media. Vibratory tumblers have shorter cycle times than barrel tumblers due to continuous cutting action. They produce a smoother, finer finish, ideal for delicate and close-tolerance parts.

- Centrifugal Disc Finishing Machines: Similar to barrel tumblers but enhanced by centrifugal force, these machines offer faster results. They are best for small parts with small media.

- Centrifugal Barrel Finishing Machines: These hexagonal or octagonal barrel systems impart centrifugal force, significantly enhancing finishing. They create an isotropic finish quickly and are well-suited for small, high-value, and impingement-sensitive parts.

Step 2: Evaluate Part Surface Requirements

Your desired finish is crucial for selecting the right process.

- Deburring: Ceramic and plastic media with edges are best. For light deburring, rounded media offers a softer action.

- Surface Finish Texture: Any media can work. Ceramic media typically gives a duller finish, while plastic media provides a brighter one.

- Polishing: Organic media (e.g., walnut shells) and porcelain pins are perfect for polishing.

- Cleaning Laser/Water Jet Cut Finish: Ceramic media is more aggressive, creating smoother edges for seamless machine feeding.

- Removing Rust: Ceramic media is highly effective due to its aggressive nature.

Step 3: Consider Part Materials

Different materials respond best to specific media:

- Stainless Steel: Typically requires ceramic media.

- Aluminum/Brass: Usually require plastic media.

- Cast Iron: Works well with ceramic media.

- Plastic: Often uses plastic media, depending on the specific plastic.

Step 4: Account for Parts Size and Shape

Part dimensions influence media and method selection:

- Very Small Parts: Best handled with ceramic media.

- Intercalate Parts: Plastic or porcelain media offer sharper action on delicate parts.

- Medium Parts: Larger media leads to shorter processing times.

- Highly Machined Parts: Can use either plastic or ceramic.

- External Threads: Light deburring often requires non-aggressive plastic media.

Step 5: Factor in Cost

Cost is a key consideration. Vibratory systems are generally more expensive than barrel tumbling machines due to their size. However, barrel tumbling systems wear out media at half the rate of vibratory systems, though they take longer to complete the same job.

Conclusion

Effective use of finishing equipment comes largely from hands-on experience. It’s essential to keep detailed records of each run to understand its effects and allow for future duplication. There’s no single “best” system; choosing the right equipment requires careful study and prior knowledge of each system’s performance is a significant advantage.