Inquire now about our VB series vibratory deburring machines to elevate your product quality and efficiency!

Our vibratory deburing machines VBs (B) are suitable for deburring and edge radiusing of aluminum, brass, copper, stainless stel, and iron workpiecessuch as machined parts, injection molding parts, stamping parts, and die casting parts.

In the vibratory deburring process, a container consisting of the workpieces and tumbling media is subiected to a controlled gyratory vibration. Thevibration causes the tumbling media and workpieces to rub against each other, resulting in a polished look.Vibratory deburing is one of the most costeffective fnishing processes as it requires minimal or no labor.

Inovatec offers continuous feed and batch feed variants of vibratory deburing machines. The unload flap and separation screen allows quick separation ofworkpieces from the tumbling media. Our VBs (B) series machine has an extended separation deck with multiple separation holes

| Model | VBS(B)100 | VBS(B)150 | VBS(B)200 | VBS(B)300 | VBS(B)400 | VBS(B)600 |

| Total volume(L) | 100 | 150 | 200 | 270 | 400 | 600 |

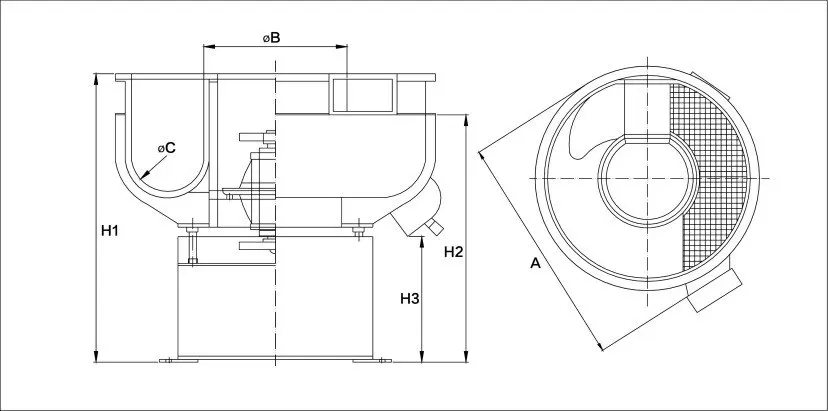

| Max overall dimension(mm) A | 1080 | 1170 | 1200 | 1370 | 1470 | 1860 |

| Motor installation tube(mm) B | φ460 | φ460 | φ530 | φ630 | φ630 | φ900 |

| Bowl Tunnel Width C(mm) | φ220 | φ260 | φ252 | φ275 | φ330 | φ390 |

| Unload width(mm) | 250 | 210 | 250 | 320 | 380 | 470 |

| Machine height(mm) H1 | 980 | 860 | 940 | 960 | 1270 | 1140 |

| Unload height(KW) H2 | 800 | 710 | 770 | 760 | 1090 | 925 |

| Media unload height(kg) H3 | 470 | 440 | 360 | 290 | 570 | 400 |

| Motor(KW) | 1.5/2.2 | 2.2 | 3.0 | 3.7/5.0 | 5.0/6.0 | 5.5/7.5 |

| Weight(kg) | 280 | 320 | 460 | 650 | 780 | 1180 |

Hot-poured PU and a heavy-duty vibration motor are the primary components in our high-performance vibratory deburing machines. Wve make ourpolyurethane using raw materials sourced from Dow Chemicals, USA.

We use an automatic casting machine to solidify the PU, then cure it at a controlled temperature for 24 hours. We use heavy-duty motor from shanghaiVibration Co. With proper maintenance, it can last more than five years

You can use our vibrato!-burring machines VBS (B) to do the following:

Sign up to get latest updates and news.

© 2025. All Rights Reserved by inovatecmachinery